What is a Medical Connector?

What is a Medical Connector?

In the world of medical technology, precision and reliability are essential. Every piece of equipment must perform flawlessly to ensure patient safety and treatment efficacy. One critical component often overlooked but fundamental to the operation of medical devices is the medical connector. Medical connectors are specialized, high-performance connectors designed for use in medical environments, enabling the safe and efficient transfer of power, data, and signals between devices.

Defining a Medical Connector

A medical connector is an interface that links different medical devices or components, facilitating electrical, optical, or data transmission. These connectors ensure that devices like ventilators, monitoring equipment, MRI machines, and surgical instruments can communicate and operate as designed, allowing healthcare professionals to deliver precise and timely care.

While connectors are necessary in many industries, medical connectors are designed to meet stringent safety, durability, and cleanliness standards that are unique to healthcare settings. They often feature high-quality materials, specialized locking mechanisms, and additional safety measures to prevent electrical faults, contamination, or accidental disconnection.

Key Features of Medical Connectors

Medical connectors must meet specific criteria to ensure they are suitable for use in healthcare environments. Here are some of the essential features:

– High Durability: Medical connectors are built to withstand repeated usage and sterilization processes, such as autoclaving or chemical sterilization. Their durability ensures they can maintain functionality through harsh cleaning cycles without degradation.

– Reliability and Precision: Medical connectors must deliver consistent performance, ensuring accurate transmission of data or power without fail. Any failure could lead to miscommunication between devices, jeopardizing patient health.

– Miniaturization: Many medical applications, especially those involving wearable or implantable devices, require connectors that are both small and lightweight. Miniature connectors reduce the overall size and weight of devices, enhancing patient comfort and allowing more precise applications.

– Safety and Compliance: Medical connectors comply with strict regulatory standards. For example ISO 13485, to ensure they meet safety and quality requirements. As a leading medical connector manufacturer, Onanon is ISO 13485 certified, demonstrating our commitment to safety in the medical industry.

– Sealed and Sterilizable Designs: Medical connectors used in environments with a high risk of contamination, such as operating rooms, often feature sealed designs to prevent the ingress of fluids and debris. We put these connectors through a testing process to ensure that they are able to withstand any liquids from entering. This ensures that the connector remains sterile and safe to use, protecting patients and medical staff.

– User-Friendly: Given the fast-paced nature of healthcare environments, medical connectors are often designed with intuitive locking and mating mechanisms that allow quick and secure connections, minimizing the risk of human error.

Applications for Medical Connectors

Medical connectors are found in a wide range of devices and systems. Here are a few key applications:

Surgical Instruments and Robotics: With the rise of robotic-assisted surgery, connectors play a critical role in transmitting commands and data between robotic arms and control systems. This allows precise movement during operations.

Imaging Equipment: High-performance connectors are used in MRI, CT scans, and 3D imaging devices to transmit data, signals, and images between components. This ensures clear and accurate diagnostic results.

Innovations in Medical Connector Technology

As medical technology continues to advance, so do the connectors that enable these devices. For example, Onanon has developed its patented MagConnect® technology, a high-voltage magnetic connector designed for medical applications like Pulsed Field Ablation (PFA). This innovative magnetic connector integrates both fiber optics and electrical connectivity, providing advanced functionality in a single, compact design.

Learn more about our PFA applications here.

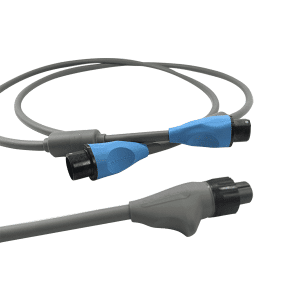

Onanon’s Neutrino and Apollo connectors are further examples of how medical connectors can be adapted to meet the unique needs of devices, such as lightweight handpieces or ventilators, combining off-the-shelf components in specialized medical cable assemblies. Read more about Onanon’s off-the-shelf medical connectors here.

The Future of Medical Connectors

As the healthcare industry evolves, so will the demands on medical connectors. With the rise of IoT in healthcare, smart connectors that can collect data or adjust performance based on the connection status, such as Onanon’s smart connectors with embedded LEDs and programmable EEPROM, are becoming increasingly common.

The growing demand for wearables, implantables, and robotic surgery tools will likely drive further miniaturization, making connectors even smaller and more sophisticated. The integration of wireless technologies, advanced materials. AI-driven systems will also shape the future of medical connectors. As a leading medical connector and medical cable assembly manufacturer, we pride ourselves on continuing to support the evolving needs of the healthcare industry.

Let’s Connect

Are you interested in partnering with Onanon?

Book a meeting with us here, or send us a note here.

To learn more about our company and our products, check out our YouTube channel.